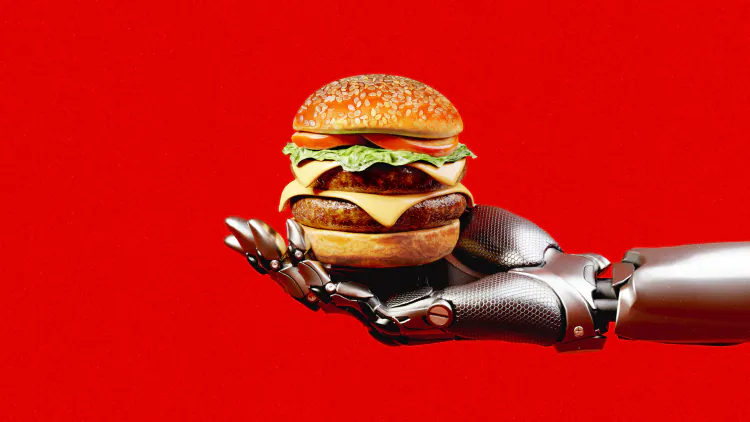

Your Fast Food Is Already Automated

The founder of Chipotle wants to reinvent lunch using robots. Is that really a reinvention at all?

Moments after receiving my lunch order, the robots whirred to life. A clawlike contraption lurched forward, like a bird pecking at feed, to snatch dishes holding a faux-chicken cutlet and potatoes, then inserted them onto a metal track that snakes through a 650-degree-Fahrenheit oven. Seven minutes, some automatic food dispensers, and two conveyor belts later (with a healthy assist from human hands), my meal was sitting on a shelf of mint-green cubbies. It was a vegan fried-chicken sandwich, a cucumber salad, crispy potatoes, and a smattering of other sides.

This is Kernel, a fast-casual venture that opened its first store in Manhattan this February. Its founder, Steve Ells, kicked off the lunch-bowl boom when he started Chipotle in 1993. Now, he told me during my visit, he is betting that machines will trigger a “reinvention of how a fast-food or fast-casual restaurant can run.” Robots, he prophesied, will bring faster and more accurate service at lower overhead costs. Plenty of chains have tested out semi-automated cooking, with mixed success—including deep-frying robots at Jack in the Box and robotic bowl assembly at Sweetgreen and Chipotle. But Kernel has been built from the ground up for robots. Just three employees are needed in the restaurant at any time, compared with the dozen needed at a typical fast-casual restaurant. Soon many more people may be eating robot-prepared vegan chicken: Ells has raised $36 million and hopes to expand quickly, starting with several more locations throughout New York City this year.

But robots may represent less of a fast-food revolution than the obvious next step in its evolution. For more than a century, technology has made fast food more efficient—and, in particular, more automated. That’s what turned McDonald’s into a giant 60 years ago. Such restaurants can be considered “sort of mini-factories,” Dave Henkes, a food-industry analyst at Technomic, told me, and have always used “automation to drive speed and convenience.” And, like the simpler cooking technology before them, today’s robots are speeding up humans’ work without fully replacing them. For now, Kernel is no different.

Kernel’s entirely vegan menu is limited (Ells prefers “focused”), but everything looked and tasted like it came from fine dining. That is no coincidence: Kernel’s chief culinary officer, Andrew Black, was a sous-chef at Eleven Madison Park, a three-Michelin-star restaurant with a $365 tasting menu, located a block away from Kernel. While I ate, he and Ells gave passionate spiels about each item: The marinated beets, a surprise best seller, are topped with quinoa, green hummus, and a seed crunch to make the dish nutritionally complete. For the crispy potatoes, Black specially selected a spud variety for its sugar, starch, and water content, and they’re then cooked three times—steamed, fried, baked—to achieve a shattering crunch and pillowy interior. Black and his staff dredge and fry every piece of “chicken” by hand; as I bit into my sandwich, Ells mused that they should try swapping imitation meat for a block of tofu.

Simply put, Kernel is a group of excellent chefs equipped with the world’s most high-tech toaster oven. All the food is cooked by chefs at a central kitchen about 10 minutes away, delivered hourly by a bicycle courier, and heated by a robot. That off-site preparation, Ells told me, provides at least 80 percent of the menu’s quality. The food then has to be assembled by still three other people. Human one, the “replenisher,” loads the hourly delivery of prepared food onto a shelf that the robotic arm can reach. The “assembler” puts together every sandwich and side, and a third person, the “bundler,” bags each order and places it in a cubby.

The setup is “extraordinarily fast, accurate, and predictable,” Ells told me, nothing less than a “paradigm shift.” Employees barely have to move their feet. But a robot that heats and moves around your food is just the next iteration in the pursuit of speed and standardization. The restaurant with the strongest claim to inventing fast food may be White Castle, which, in 1921, “did something that was unusual for the time—they tried to standardize their operations from restaurant to restaurant,” David Hogan, a fast-food historian at Heidelberg University, in Ohio, and the author of Selling ’em by the Sack: White Castle and the Creation of American Food, told me. Cooking procedures were precise and uniform; cooking implements were manufactured in a single location; even the physical buildings came out of a central factory.

The playbook hasn’t substantively changed since. Before buying McDonald’s and launching its global success, Ray Kroc sold the chain automatic milkshake mixers. What first captivated him about the restaurant, he wrote in his 1977 memoir, was how “each step in producing the limited menu was stripped down to its essence and accomplished with a minimum of effort.” That year, the Bureau of Labor Statistics published a study noting that fast-food chains had “introduced principles of industrial engineering” to restaurants. In particular, “the off-premise preparation of foods” and improved “cooking devices,” such as microwaves and convection ovens, reduced preparation time and added uniformity. Restaurants today use specialized equipment, extensive training manuals, and various trackers to ensure speed and consistency. Sweetgreen has an app that instructs employees exactly how to heat and prepare food, and McDonald’s cooks beef patties for precisely 42 seconds. If anything, Kernel’s off-site kitchen is conceptually closer to the centrally prepared, frozen patties and fries served by fast-food burger joints of old than the chicken grilled on-site at a Chipotle.

To the extent that Kernel is a reinvention, Ells hasn’t invented a new paradigm so much as found another. Sweetgreen already acts like a tech company, and Domino’s has touted itself as one. Now Ells talks about his robot-assisted process as an “operating system.” What may one day distinguish Kernel’s automation is that the space is designed for robots from inception. So far, other chains have retrofitted human kitchens with robots, which creates confusion and disaster, Stanislav Ivanov, who studies robotics and restaurants at Bulgaria’s Varna University of Management, told me. Robots malfunction and, even when they don’t, bulky machines interfere with equipment, stations, and a floor plan designed for human movement. In 2018, an early burger-flipping robot that was tested at a CaliBurger in Pasadena was temporarily decommissioned because it couldn’t be incorporated into the human workflow.

Kernel is, at least in theory, built for “the technology that we know is coming,” Ells said. The equipment is all mobile and can be swapped or calibrated for newer gadgets (permanent counters, ovens, and stovetops, for instance, are unnecessary because robots don’t care if work stations are waist-height). Drones could bring prepared food from the central kitchen to restaurants, and robots might assemble burgers in their entirety. Efficient robots and a vegan menu, he said, will continue to reduce the restaurant’s carbon footprint. Gesturing to the “bundler” who bagged all the food, Ells said, “Instead of Carlos, imagine a robot arm” (Carlos kept bundling without so much as a flinch).

With automation, of course, comes the risk of disappearing jobs. Kernel and other restaurants are experimenting with robots not only in pursuit of efficiency, but because the industry is facing a chronic labor shortage. The low pay doesn’t help, and the jobs are also exhausting as well as, at times, hazardous. Deep-frying, for instance, is extremely dangerous, which is why one of the most popular cooking robots in the industry simply runs the fry station. Fast-food chains pursuing automation are trying to reduce head count, especially as some states raise their minimum wages. But for now, Henkes said, robots have typically led restaurants to redeploy people to different positions. Ells claimed that Kernel’s existing employees, who are currently paid $25 an hour, will eventually be moved to more front-of-house jobs, helping guests and monitoring the robots.

But a burger prepared, cooked, and served without a human touch is still more accurately described as speculation. Faster and more automated cooking technology may well be imminent, but humans will still be involved for years to come. Automated pizzaiolos, line cooks, and salad tossers have failed; successful robots typically target a specific task, like plunging fries into boiling oil.

Just as the quality of Kernel’s food depends on human chefs, the quality of its automation will depend less on technology than on human vision and feedback. Each day, employees meet to discuss what worked and what didn’t, which will help iterate the technology: Dozens of bugs, including stalled production and locked cubbies, have been smoothed out. On the first day, the cubbies didn’t open; last month, a stray potato shut down Kernel’s production line. Kernel is building new tools, but relying on the same human logic that made White Castle, McDonald’s, and Chipotle successful. I came to the restaurant to witness fancy robots, but I would return simply for the faux-chicken sandwich and the cucumbers topped with cashews and chili jam. Kernel the restaurant is far more impressive than Kernel the tech company.

What's Your Reaction?